Loctite® 3D PRO9274 Resin Compared

Henkel Unveils Loctite 3D PRO9274 Resin: A Durable Workhorse for Industrial 3D Printing

For decades, Loctite® has been a household name in adhesives and sealants. Their innovative formulas have secured countless nuts and bolts, and their products have played a vital role in various industries. Now, Henkel’s Loctite is leveraging their expertise in material science to revolutionise the world of 3D printing with the introduction of the Loctite 3D PRO9274 resin.

Henkel established its Loctite 3D Printing business unit in recent years, recognizing the immense potential of this transformative technology. Their focus lies on developing high-performance resins specifically tailored to industrial applications. Loctite’s 3D resins undergo rigorous testing producing reliable trustworthy data. These resins prioritise characteristics like durability, precision, and compatibility with various DLP/LCD printer technologies.

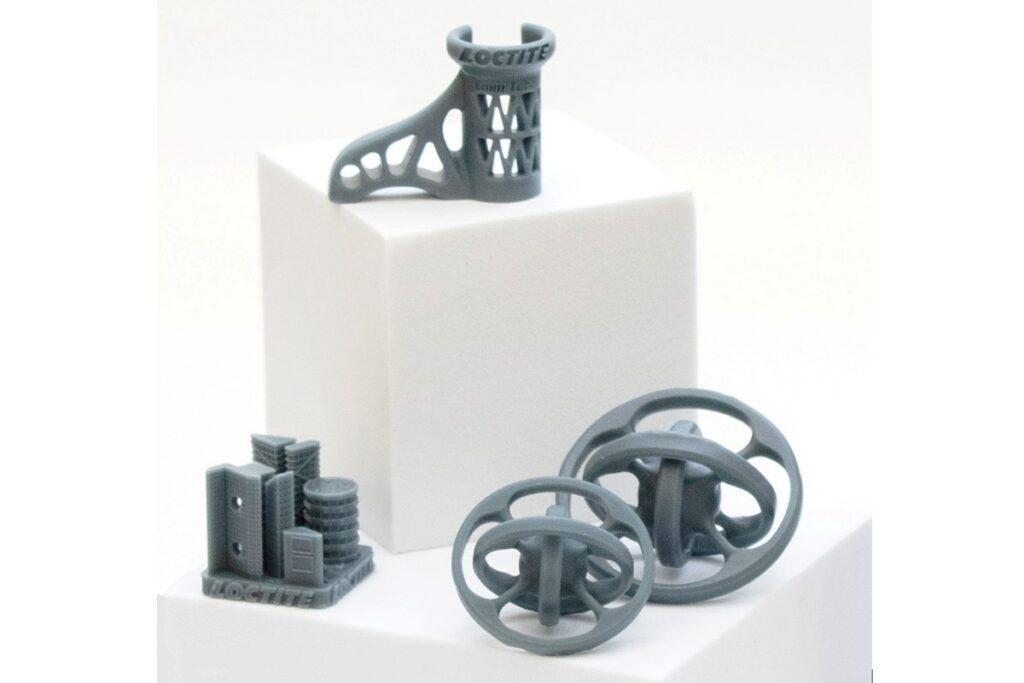

The latest addition to their portfolio, the PRO9274 resin, embodies this philosophy. This dark gray resin stands out for its ability to deliver several key benefits:

- Exceptional Speed and Detail: The PRO9274 boasts fast printing speeds, allowing for rapid prototyping and efficient production runs. This is particularly advantageous for companies that require quick turnaround times or need to produce large volumes of parts. Furthermore, the resin produces highly detailed prints, ensuring intricate designs are faithfully reproduced in the final product.

- Robust Durability: One of the hallmarks of Loctite products is their strength and reliability. The PRO9274 upholds this tradition, offering exceptional durability that makes it ideal for functional parts. Whether it’s a mechanical housing, a prototype for a power tool component, or an end-use product itself, the PRO9274 can withstand significant wear and tear.

- Cost-Effective Versatility: In the realm of 3D printing, high-performance materials often come at a premium price. However, the PRO9274 strikes a balance between exceptional characteristics and affordability. This makes it a cost-effective choice for a wide range of industrial applications. Additionally, the resin’s compatibility with various DLP/LCD printers enhances its versatility, allowing companies to leverage their existing equipment without needing to invest in specialised printers.

FEPshop is looking for Testers

FEPshop is looking for companies & Makers to test Henkel Loctite 3D’s new Loctite 3D PRO9274, in real-world projects. If you use LCD or DLP resin printers, apply now for a chance to get 2KG of PRO9274 resin for free. Don’t miss out – Apply today!

Applications for the PRO9274 Resin

The combination of speed, detail, durability, and cost-effectiveness makes the PRO9274 resin suitable for a diverse range of industrial applications. Here are some potential areas where this new resin can shine:

- Rapid Prototyping: The fast printing speeds and high-resolution capabilities of the PRO9274 make it perfect for creating prototypes quickly and efficiently. This allows engineers and designers to iterate on designs rapidly, leading to faster product development cycles.

- Parts finishing: The professional-grade material can be easily spray-painted due to its gray base colour, and it can be printed quickly on low-entry printers.

- End-Use Products: In some cases, the PRO9274’s properties may make it suitable for direct use in finished products. This could be particularly relevant for applications where strength, detail, and cost-efficiency are all crucial factors.

Understanding the Mechanics: Material Properties of PRO9274

To fully comprehend the capabilities of the PRO9274 resin, it’s important to delve into its key mechanical properties. These properties define how the resin behaves under stress and strain, ultimately determining its suitability for different applications.

- Tensile Strength: This metric indicates the force required to pull a material apart. A high tensile strength signifies the material’s ability to resist breaking under tension.

- Flexural Strength: Also known as “modulus of rupture,” this property measures the material’s resistance to bending forces. A high flexural strength is essential for parts that experience bending stress during operation.

- Heat Deflection Temperature (HDT): The HDT signifies the temperature at which a plastic material begins to deform under a constant load. A high HDT indicates the material’s ability to perform well in elevated temperatures.

- To learn more, click on link to access the Technical Datasheet

- To learn more, click on link to access the Product Page